Actuation solutions

Trusted by major Oil & Gas companies worldwide, our actuators are designed to optimize space, cost, and performance in any environment.

Why Us?

With more than 60,000 combined years in operation worldwide and preferred vendor status with leading Oil & Gas companies, ATC delivers products that combine Dutch engineering excellence with global service and support.

Pneumatic Actuators

Versatile and compact actuator enabling cost optimization.

• Output torque up to 1,000,000 Nm.

• Pressure range: 4–12 barg.

• Compact & Reduced Height series.

• No external tie-rods, increasing reliability.

• Optimized for piping layout, weight & footprint reduction.

Key benefit: maximum reliability and cost of ownership optimization for onshore & offshore projects.

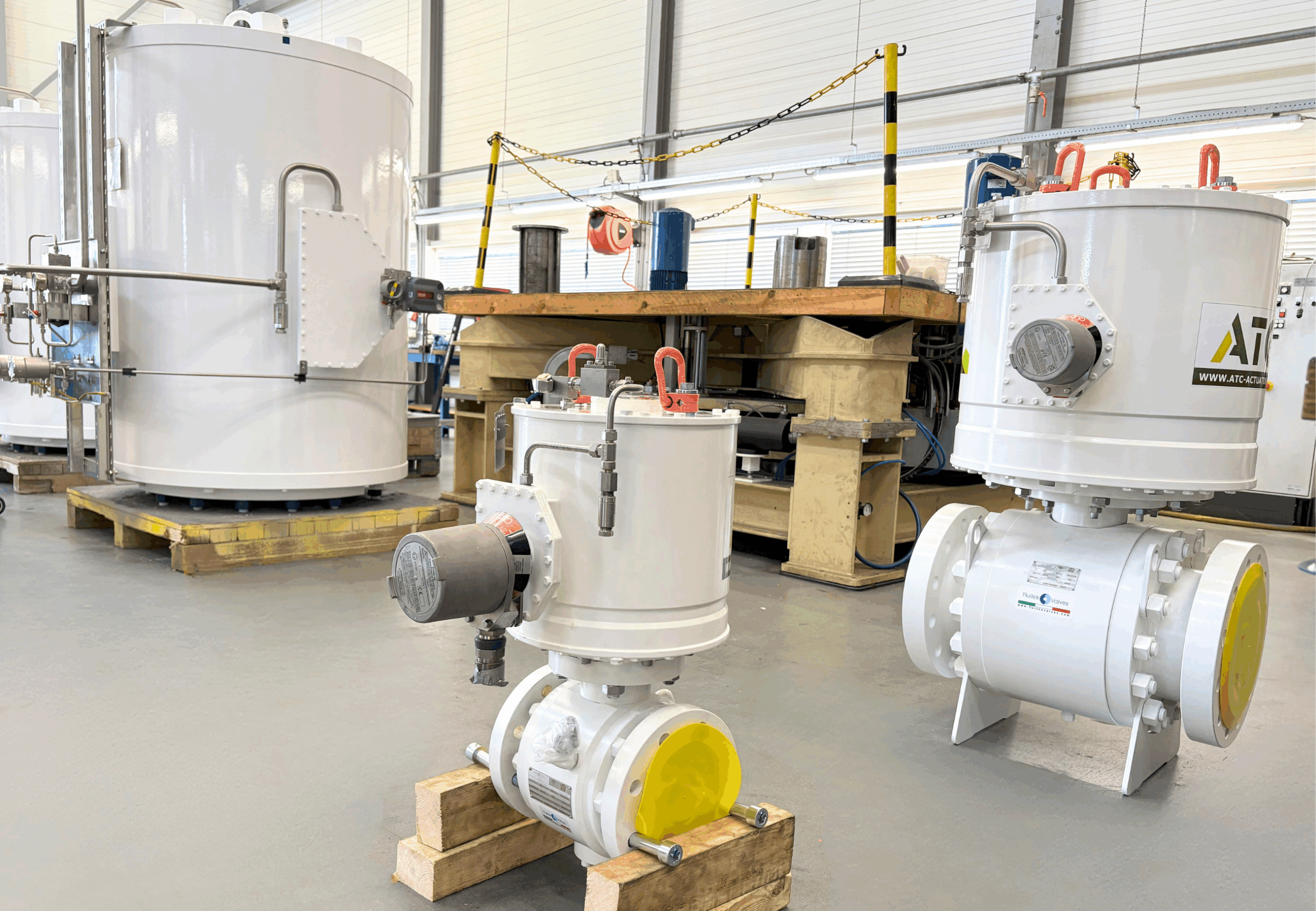

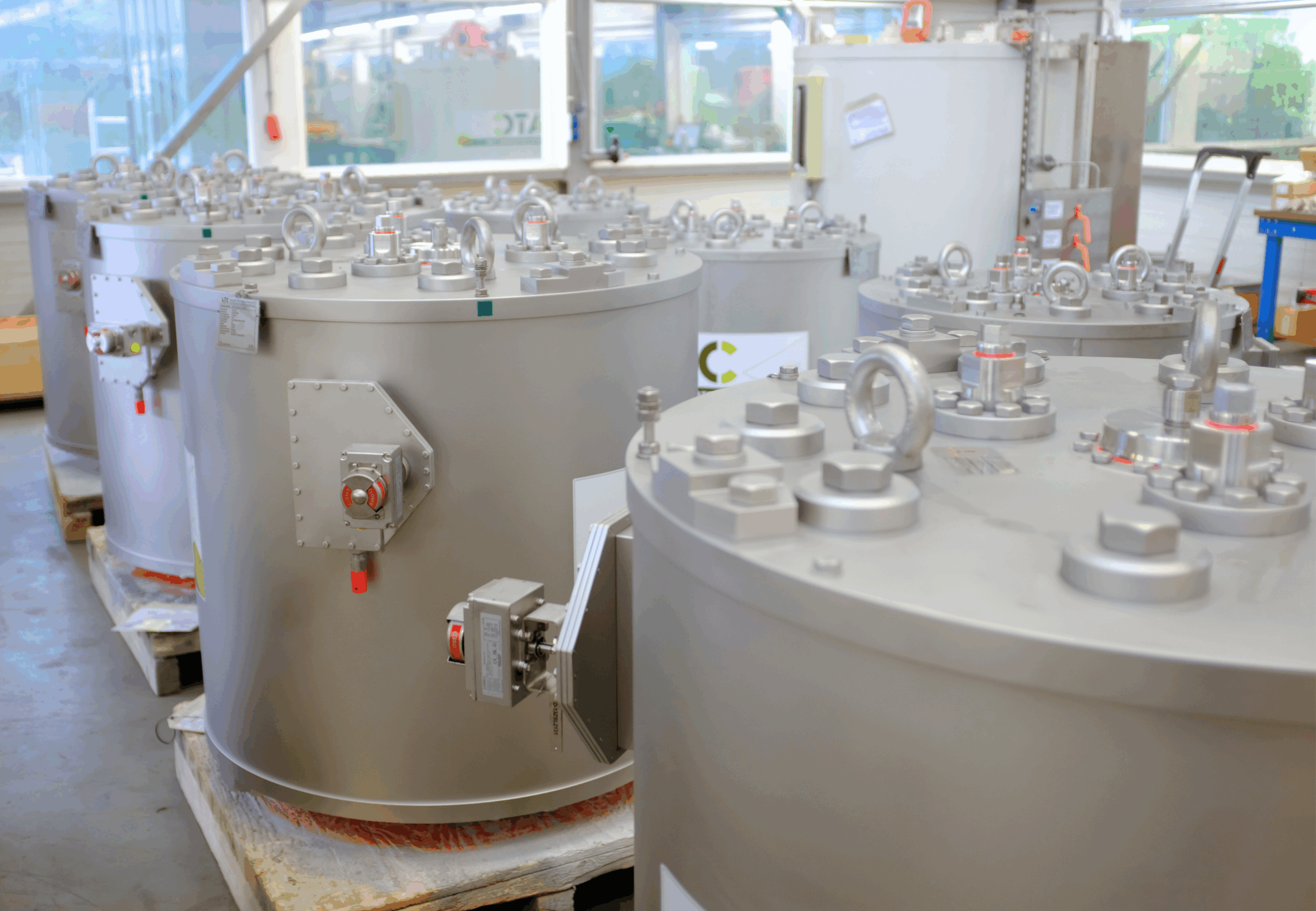

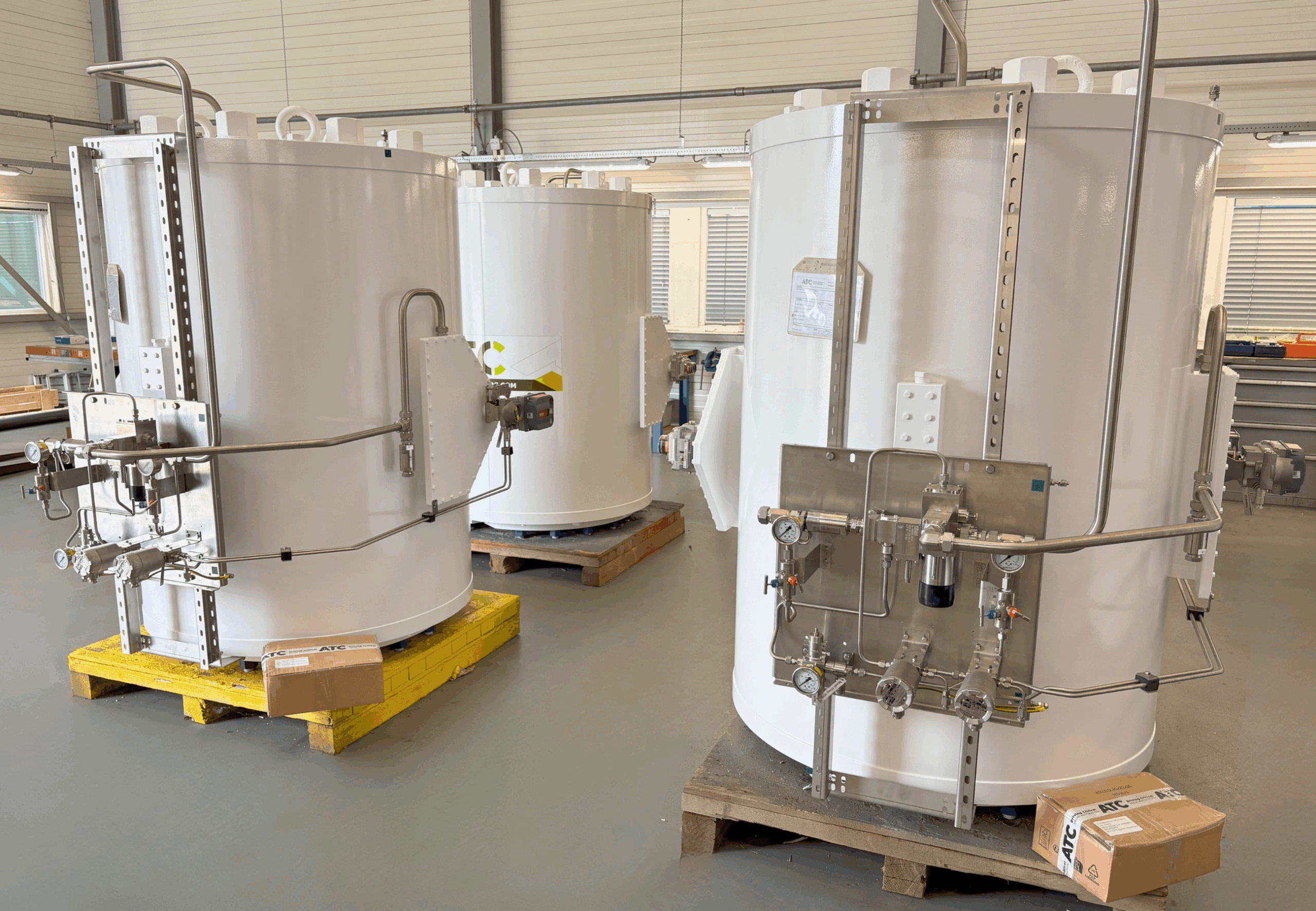

Hydraulic Actuators

Engineered for subsea and topside reliability, with torque outputs up to 1,000,000 Nm.

• Helical slot-type torque-efficient design.

• Spring return & double-acting models.

• Hermetically sealed for subsea & topside use.

• In-house hyperbaric & performance testing.

Key benefit: robust and reliable performance under extreme conditions

Accessories & Control Systems

Topside control panels

Regardless the actuated valve functionality is HIPPS, emergency shutdown, blowdown or on/off application, we have the capabilities to design and build the local control panels fully according the project specifications.

We have extensive experience with the typicals and standard layout types that are used by the different end users and EPC compnanies.

Subsea control panels

ROV and/or diver operatable subsea control panels.

Including hot stab override as per API 17H / ISO 13628-8.

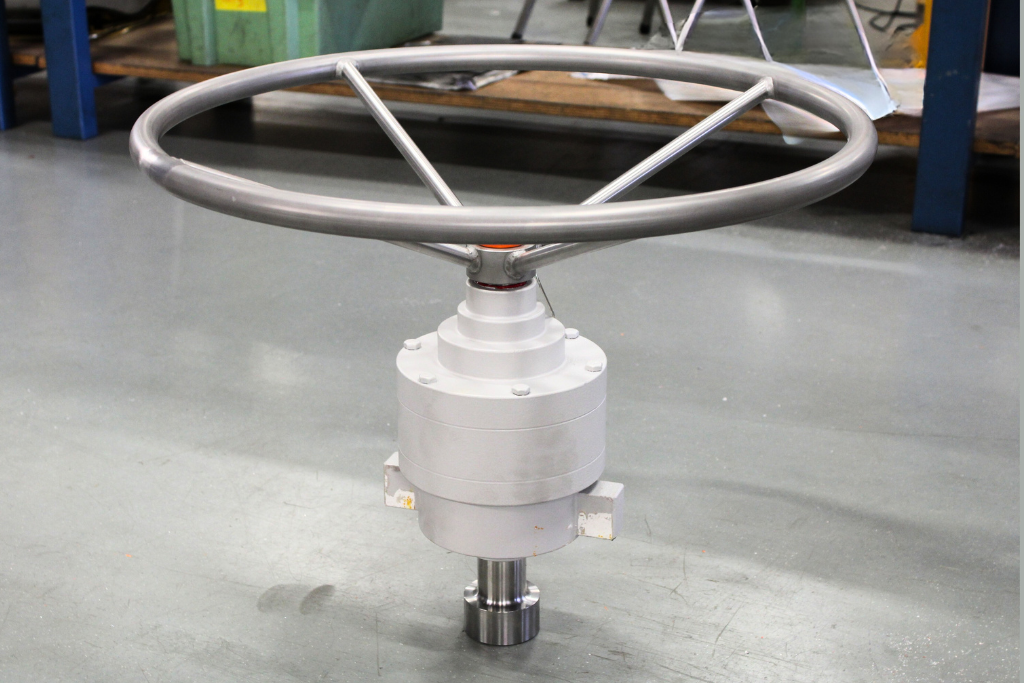

Gearbox - ROV or diver operated

Field-proven worm gear design.

• Spindle extentions available for both horizontal & vertical access.

• ROV interface and/or diver operation by handwheel

• Output torques up to 1,000,000 Nm

• Shallow water (up to 250 m) & subsea deep (up to 3000 m) executions

• Declutchable gearbox override option available

• In-house hyperbaric & endurance testing available

Clamp systems for ROV retrievability

Clamping systems for easy retrievability and re-installation of actuator and/or gearbox subsea by ROV. Running tool interface available as option

Handwheel adapters for divers

Removable handwheel adapters suitable to connect with ROV API 17H / ISO 13628-8 interface suitable for diver intervention.

Customization of torque output

The ATC helical torque conversion system matches most typical valve torque curve, reducing oil or air displacement by up to 50%.

In case there is a non-typical torque curve required we can modify the slot and curve output design to match the valve requirements and thus further optimizing the size and displacement of the actuator compared to traditional type actuator.

Known applications are large, high pressure rated valves with high breaking torque and/or overlap angles.

Stainless steel actuators

In specific cases there is a need for stainless steel casing / exterior of the actuator for protection against harsh and corrosive environments.

All our actuators can be executed in stainless steel material like SS316, duplex, etc.

Arctic temperatures

With our engineering knowledge and experience we have supplied several projects that required an actuator design suitable for arctic conditions with temperatures down to -52 degr C.

Special material selection and design customization are part of our company expertise.

Why is the compact actuator design superior to traditional pneumatic actuator mechanisms?

ATC’s compact actuator, featuring a helical slot design, delivers equal or higher torque than traditional mechanisms in a smaller, more efficient package. It’s low-friction torque conversion system that precisely matches the valve torque curve, reducing oil or air displacement by up to 50%. With fewer components, a self-lubricating mechanism, and an integrated casing that houses the piston, spring, and torque transmission system, ATC’s compact actuators offer higher reliability, lower maintenance, and longer operational life compared to conventional rack & pinion or scotch yoke designs.

Which actuator type is more cost-effective?

Over the full life-cycle, pneumatic actuators are typically more cost-effective. They don’t require an HPU, use lower-cost components, and have minimal maintenance needs. This results in reduced downtime and faster project deployment.

Can pneumatic actuators deliver high torque too?

Yes, modern compact pneumatic actuators can now operate large, high-pressure valves that once required hydraulic actuation. The latest designs combine robust torque performance with the simplicity and low weight of pneumatics, optimizing energy use and space in facilities

What about installation space and versatility?

ATC’s compact actuator design optimizes space, weight, and overall investment. Its integrated mechanism and reduced footprint make installation easier and more flexible — whether in existing facilities or new projects. Ideal for confined areas such as offshore platforms or modular skid units, the lightweight, space-saving design simplifies assembly, reduces total system weight, and helps lower project costs while maximizing efficiency and layout flexibility.

Contact form

We value every opportunity to connect with our clients and partners worldwide. Whether you need technical support, product information, or commercial assistance, our team is ready to help.

Unlock the future of critical valve automation

Need Support or Specifications?